Have you ever wondered how an electric golf trolley is built? Despite the number of trolleys we’ve tested at Golf Monthly over the years, we were still none the wiser as to how they are actually designed, engineered and assembled before they head out onto the golf course.

Luckily for us, Stewart Golf, market leaders in designing and engineering remote electric golf trolleys, invited us down to its factory in Gloucestershire to see exactly how its 2025 Q Follow trolley is designed and built. Not only that, but we’d be helping out on the assembly line, too. The new 2025 Q Follow trolley has arrived with improved 8th generation Follow technology, greater customisation with six new colourways and an integrated rangefinder mounting plate – and we’d be building one of the very first new models to roll out of the factory.

Indeed, the exact 2025 Q Follow trolley you will watch being built in the video below is also being given away to one lucky entrant. You can find out how to enter the competition at the end of this article.

WATCH: Dan Parker builds his very own 2025 Q Follow trolley at Stewart Golf’s HQ

Goods In & Quality Assurance

(Image credit: Howard Boylan)

We started our day at the far end of the warehouse, otherwise known as Goods In. Here, as the name suggests, is where every part for every Stewart Golf trolley arrives before it is put through its paces by the quality assurance team, which will make sure each part. We were joined for the day by Stewart Golf CEO Mark Stewart, who talked us through the processes behind making an electric golf trolley at Stewart Golf.

“All of our parts are made by specialist subcontractors, mostly in the UK,” Mark explained. “Everything comes through this door, and this is where we’ll check for quality and make sure everything is doing what we want it to do and is made how we’ve designed it.”

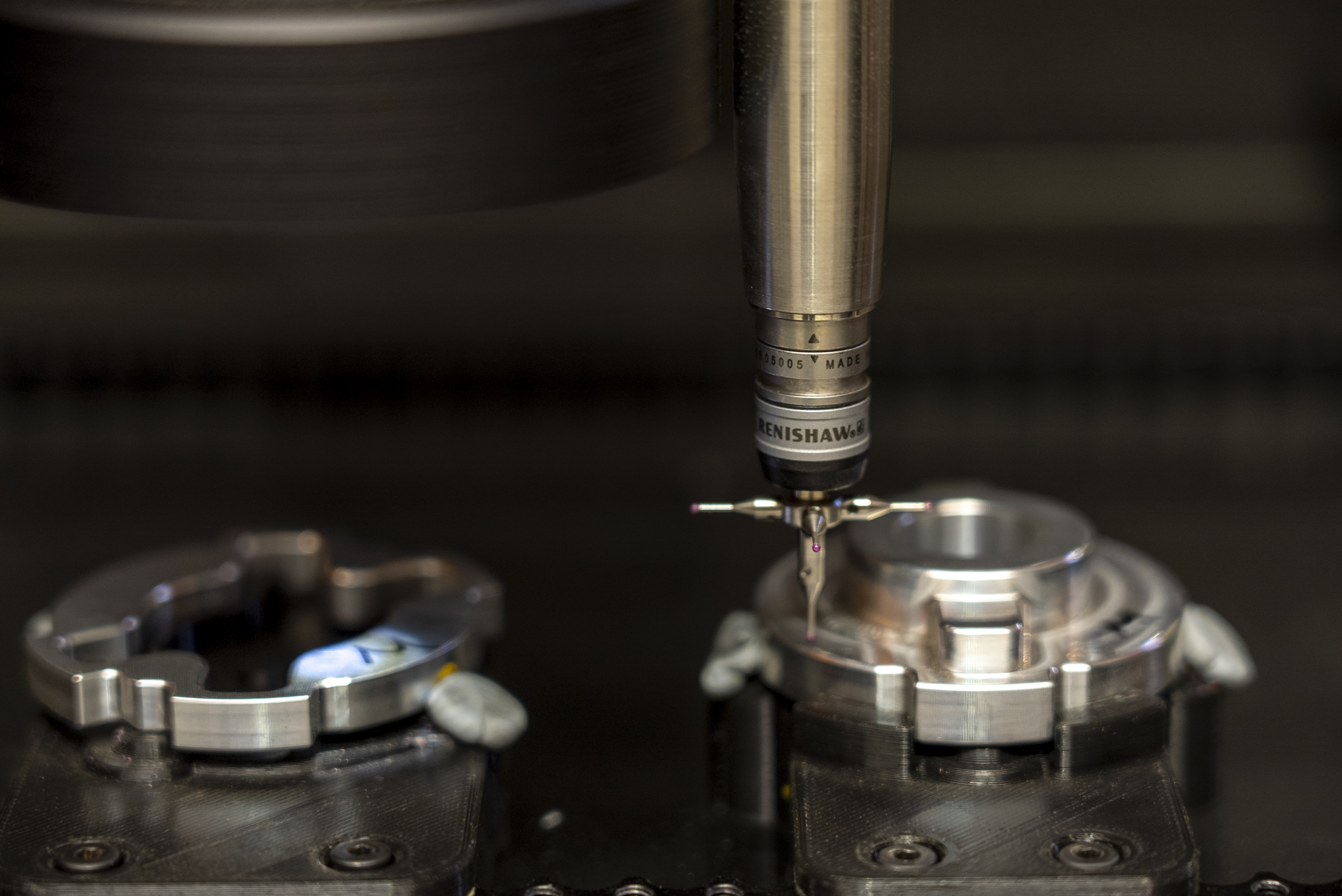

The engineers at Stewart diligently check all the parts that come into the factory before they hit the assembly line. A cutting-edge measuring machine is on hand to precisely measure and check even the most awkwardly shaped part of a Q Follow trolley down to the millimetre.

The five prongs on the end of this machine can measure the exact specifications of a part of the Q Follow trolley to make sure it has arrived at the factory ready to be a seamless part of the assembly line.

(Image credit: Howard Boylan)

“It could be anything, so even the wheels of the trolleys. How do we know for sure that the wheel is round? How do we know that all of…

..

Click Here to Read the Full Original Article at Latest from Golf Monthly…